Tungsten Manufacturing Operations

Requirements to Produce our Quality Certified Tungsten Products; tungsten ball, tungsten, sphere, tungsten cube are:

- People: Metallurgical, Mechanical, Chemical, and Industrial Engineering staff coupled with Technical Operators and Machinists.

- Equipment: Customized. High-Tech Machinery and Systems.

- Processes: Fully Integrated Chemical, Mechanical and Industrial Manufacturing Processes.

Incoming Powder Receiving & Testing

Fette-Powder Compacting

De-Binding

Sintering

Tumbling

Annealing

Sorting

Grinding

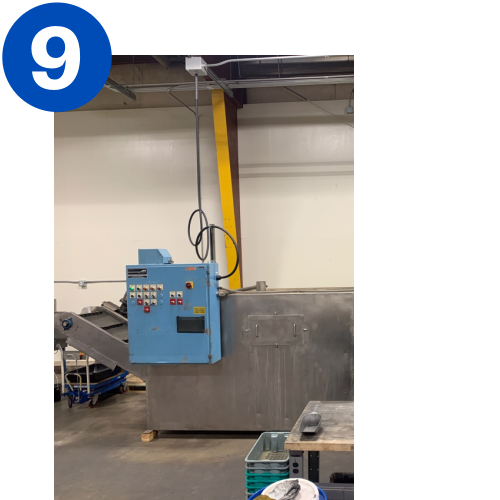

Cleaning-Washing

Sizing-Roller Meter

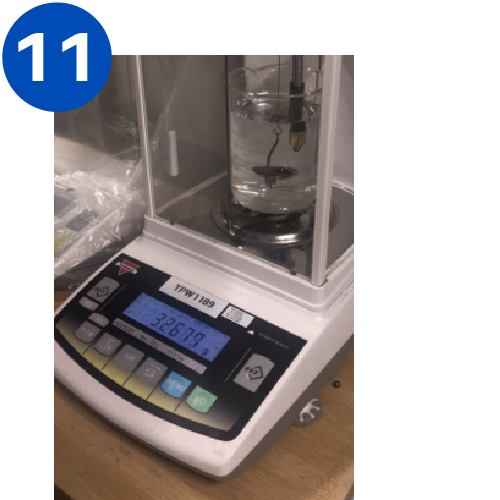

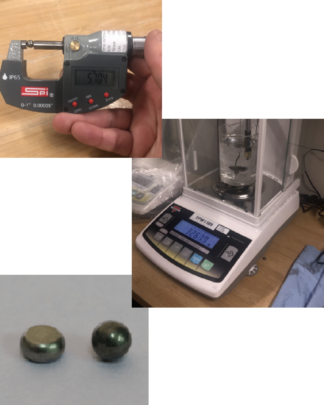

Quality Testing

Shipping

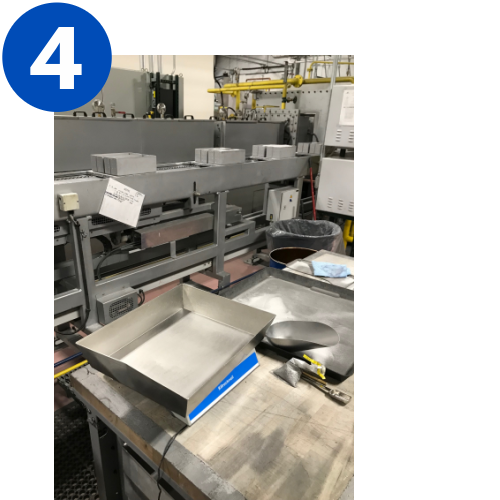

Powder Metallurgy & Pressing Systems

- Verified for composition, density, flowability and size

- Once approved by our Quality Lab, the powders are pressed into a variety of shape, held together with a proprietary binder

- The pressed parts are then heated in a series of high temperature, thermal processing steps. These heat treatments convert the powder compacts into solid fragments of tungsten heavy alloy

- Product finishing often includes grinding to size, producing perfectly shaped spheres and cubes

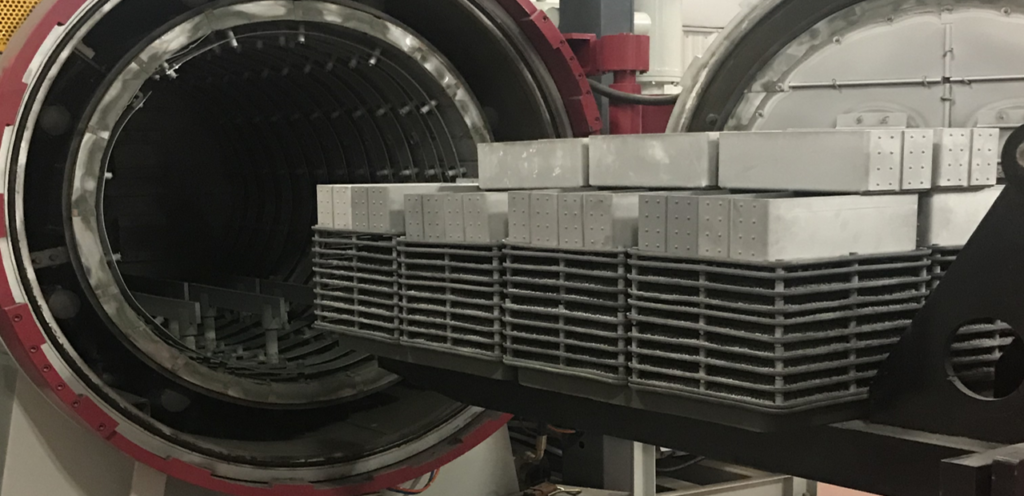

Thermal Processing

Debinding

Liquid-Phase Sintering

Vacuum Annealing

Three Separate Heat Treatment Processes Required to Produce High-Density Tungsten Alloy Products:

- Debinding

- Liquid-Phase Sintering

- Vacuum Annealing

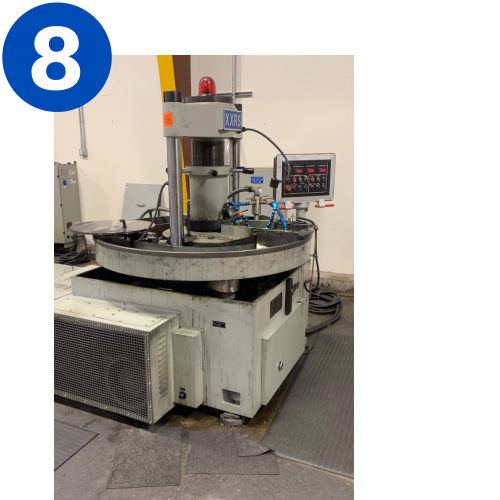

Tumbling, Sorting & Grinding

- The steps to produce uniform and extremely precise fragments is no small feat!

- Creative solutions to seemingly simple problems often lead to new innovations

- Largest grinding facility is the largest in the United States

Cleaning, Sizing & Verification Inspection

Our metallurgical process begins with raw materials, a blend of tungsten and other metal powders

- Delivering clean, precision products is critical to our Quality Commitments

- Ensuring compliance with our customer specifications involves no less than seven steps in the verification Process

- Inspecting products takes time and extreme attention to details