Executive Summary:

My design, the .408 CheyTac® cartridge, ballistically outperforms the .50 BMG in kinetic energy past 400 yards. My armor piercing design in the .408 caliber ballistically outperforms the .50 BMG armor piercing — AP (both silver and black tip) using 1-inch armor steel at 100 yards as a benchmark while maintaining Sub MOA out to 600 yards.

The US Army is in the initial stages of lightening by 20 to 30%, the .50 caliber M2 machinegun by replacing many of the steel components with titanium components — an 84-lb platform goes to 74-lb platform. The goal is to make the M2 machinegun more mobile on the battlefield as well as reducing shipping costs to the battlefield. I argue the goal fails.

We propose the US Army fund a research program to take advantage of my previous 40 caliber research to not only lighten the M2 machinegun design but also to downsize it as well for a cartridge in .408 and .408 AP calibers. The logic is that these two 40 caliber cartridges outperform .50 caliber, in both ball and AP configurations. Using these .40 caliber cartridges in a machinegun platform, identical but smaller and lighter than the current .50 caliber M2 platform would create a new battlefield tactics: increase ballistics performance of the M2 in a smaller and lighter platform.

GOAL: We proposes to downsize and lighten the M2 design chambered for the .408 caliber cartridge. This would include replacing steel alloy components with lighter metal alloy components such as titanium. This new M2 platform could be used with 3D design tripod or mount for land, water or air vehicles. The benefits would increase mobility and ballistic effectiveness while at the same time, a reduction in transportation costs,

SIGNIFICANCE: Replacing an 84-pound firing platform with a smaller 35-pound M2 platform that shoots a smaller cartridge (.408 CheyTac®) that is ballistically superior to a 1918 cartridge (.50 BMG) in both ball and armor piercing configurations.

Question:

John Browning finished his 50 caliber machinegun in 1918, entered it into the US Military in 1921 as the M2 and filed a patent in 1923. It has become a legend as the “Ma Deuce.” Will it be easy to replace a legend with a smaller and lighter 40 caliber machinegun with superior external ballistics to the 50-caliber cartridge? To do so would mean the retirement of a vast number of M2 machineguns in service backed by numerous warehouses full of .50 caliber ammunition – clearly a remote possibility. Or is it?

Introduction:

Toward the end of the 20 th Century, I proposed the need for a very long-distance sniper cartridge — one designed with an extremely low drag coefficient with enough projectile energy to incapacitate the enemy at 2000 meters1. At the time, some had focused on the 1918 machinegun .50 BMG cartridge, with its high drag coefficient projectile design requiring a “sniper firing platform” much larger than what was being used at the time.

I designed a cartridge smaller than the .50 BMG, but larger than the, the .338 Lapua Magnum promoted by Malcolm Cooper of Accuracy International. I selected the .505 Gibbs, a turn of the century dangerous animal cartridge as the starting point. This low pressure cartridge case required increasing base (aka web, head etc.) thickness as well as increasing the thickness the case wall where it joined the base. The shoulder was set at 25 degrees for easy chambering and the caliber was reduced from .505 to .408. It was called the .408 Cheyenne Tactical™ cartridge – later to be known as the .408 CheyTac®2, 3. With time the case was modified to accommodate .375 projectiles. Initial designs of the projectile were based on ratioing up the 300gr .338 SMK to .408 with and without driving bands. Later the final projectile design came from PRODUS software design with ballistic coefficient greater than 1.0 and was patented under the name of Balance Flight4. Doppler radar testing at US Army Proving Grounds, Yuma provided solid evidence that the projectile retains its trajectory path from supersonic to transonic and finally to subsonic velocities – at the time of testing the only projectile seen by Doppler radar technicians to exhibit that characteristic. A new projectile design5– from .17 to 20mm calibers, was designed to outperform the Balance Flight.

The .408 CheyTac® cartridge made its debut with the US Marines in the Second Battle of Fallujah. At the time, al Qaeda believed our maximum range capability was 1000 yards, but that day the Marine snipers were engaging combatants at 1.5 miles plus. Al Jazeera published an account that the Marine snipers were not fighting fair as a result of their new sniper rifle and cartridge.

External Ballistics Data: .408 vs. .50 in Ball and Armor Piercing Configurations:

The .408 cartridge is approximately 20% shorter than the .50 cartridge. The .408 projectile is approximately 35% lighter than the .50 projectile. The .408 cartridge is 45% lighter than the .50 cartridge. We argue the .408 cartridge is ballistically superior to the .50 cartridge.

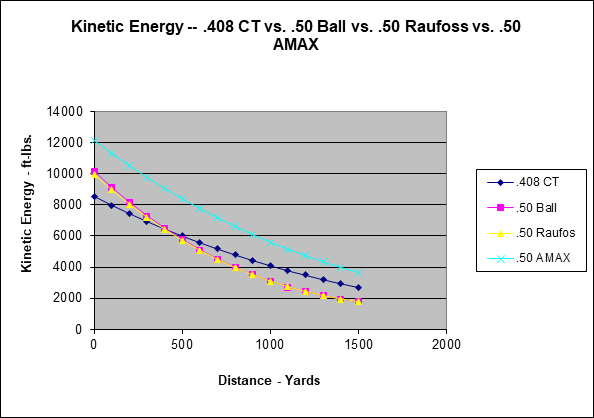

Figure 1. The .408 cartridge was contrasted against the .50 BMG ball, .50 Raufos and the .50 AMAX cartridges. Even though the .408 has a smaller projectile, it outperformed two variations of the .50 with their larger projectiles in kinetic energy over a distance of 1500 yards. The exception is the AMAX, a Hornady design for civilian shooters.

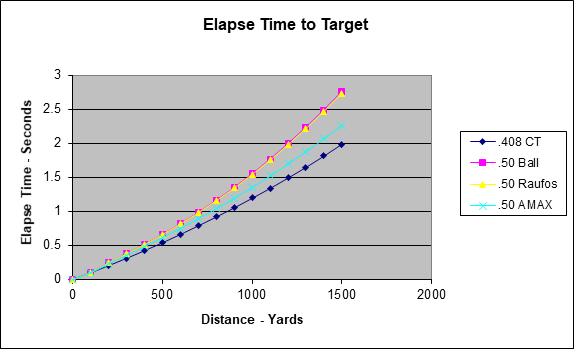

Figure 2. The .408 cartridge was contrasted to the .50 BMG, .50 Raufos and the .50 AMAX cartridges. The .408 elapse time to the target was better than the three variations of the .50 cartridge.

Velocity

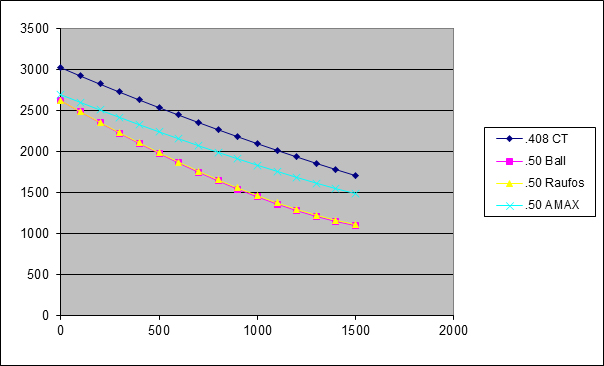

Figure 3. The .408 cartridge was contrasted to the .50 BMG, .50 Raufos and the .50 AMAX cartridges. The .408 velocity to the target was better than the three variations of the .50 cartridge due to a reduced drag coefficient.

EXTERNAL BALLISTICS COMPARISON

50 CAL. BMG M33 BALL vs. .408 CheyTac 419 Gr. Ball

50 BMG Velocity Adjusted for M82A1 Data for .408 CheyTac Barrett rifle.

BULLET WEIGHT (gr): 660 BULLET WEIGHT (gr): 419

B. COEFFICIENT: .630 B. COEFFICIENT: .949

SIGHT HEIGHT (in): 2.50 SIGHT HEIGHT (in): 3.00

meter PATH VEL ENRGY TOF PATH VEL ENRGY TOF

—– ————————— —————————

0 -2.50 2770 11243 0.0000 -3.00 2890 7769 0.0000

100 -2.83 2613 10002 0.1222 -2.55 2782 7199 0.1222

200 -11.86 2461 8875 0.2532 -10.51 2677 6665 0.2364

300 -27.96 2314 7848 0.3932 -24.32 2574 6163 0.3619

400 -51.63 2172 6914 0.5392 -44.51 2473 5690 0.4931

500 -84.20 2035 6069 0.6953 -71.95 2375 5245 0.6320

600 -126.69 1903 5309 0.8616 -106.42 2279 4830 0.7735

700 -180.99 1778 4630 1.0410 -148.84 2185 4440 0.9206

800 -248.22 1658 4027 1.2322 -200.08 2093 4074 1.0745

900 -330.14 1545 3496 1.4363 -260.40 2003 3732 1.2336

1000 -429.96 1440 3037 1.6577 -331.53 1916 3415 1.4016

1100 -548.42 1343 2644 1.8927 -413.71 1831 3119 1.5765

1200 -689.48 1257 2315 2.1458 -508.66 1749 2845 1.7606

1300 -857.98 1181 2042 2.4214 -616.93 1670 2593 1.9529

1400 -1046.68 1119 1834 2.7006 -739.94 1593 2362 2.1541

1500 -1267.04 1067 1668 3.0012 -878.71 1520 2150 2.3643

- All data is based on flight data obtained during testing at Yuma Proving Grounds, 18 June 2001.

- Ballistic coefficient values are a 1500 meter average for the purpose of this report. They are calculated for standard atmospheric conditions of 59 deg. F, 29.53 in. Hg. Air pressure, 78% humidity, sea level.

- The .408 retains its energy and velocity due to its high ballistic coefficient and a patented design. While starting at a lower energy value at the muzzle, the .408 retains a higher energy level at ranges past 800 meters.

- Additional data is available on “tactical” application such as Danger Space data, wind deflection of the .408 vs. 50 BMG, and the 338 Lapua Magnum.

Figure 4. Example of raw data collected via Doppler radar at Yuma Proving Grounds. The .408 was contrasted against the .50 ball.

Results of the External Ballistics Data:

Contrasting the external ballistics data of the .408 CheyTac® with a 419gr projectile, it is clear the .408 is ballistically superior to the .50 BMG in three configurations: Ball, Raufur and AMAX – the exception is the AMAX in KE. Finally, we have improved the ignition system of the 40 caliber cartridge without an increase in chamber pressure (Taylor & Omanoff, unpublished). Improving external ballistics is now being tested.

Types of Armor:

Armor can be found in specific types of steel alloys, ceramics, aluminum alloys and recently titanium alloys. Several common examples include Omega Armor and WearAlloy ® Armor. The major disadvantage to steel armor is weight. Weight has always been a major concern to the military. As a result, a substitute for armor steel has been a focus leading to ceramics, aluminum and titanium armors. Recent reports suggest that titanium alloy’s ballistics performance is an attractive alternative to steel alloys. For example, it has been reported that Ti-6Al-4V and Ti-6Al-4V ELI provides better projectile resistance than certain steel or aluminum alloys. Most of the studies deal with projectiles of calibers 15mm plus and are associated with attacks on armored vehicles.

Ceramic armor normally is found in a tile configuration. It defeats armor-piercing projectiles by breaking up the projectile in the ceramic material and absorbing the fragments’ energies in the plates, which back the ceramic tiles. During this process, damage is produced in the ceramic armor. Multiple hits in the same area are usually controlled by the size of the tile. Stress from one tile to the next is minimized.

Even though useful to examine all types of armor in establishing the physical characteristics of a newly designed armor-piercing projectile, it seems reasonable to use armor steel for such studies. Many of the effects on armor steel can be readily compared to other types of armor material, but it may be difficult to compare results from a non-steel armor back to steel. As a result, armor steel was used in this study, specifically WearAlloy armor or AR 550.

A new type of titanium armor from Allegheny Technologies became available to us during this study. The armor was made up of laminated titanium plates. Even though an extensive study was not conducted, limited results are presented.

Terminal Ballistics Data: .408 vs. .50 in Ball and Armor Piercing Configurations:

Most common armor-piercing cartridges are those with a copper jacketed projectile surrounding a penetrator. Rather than a copper jacket, the .408 armor-piercing cartridge starts its manufacturing with a solid alloy projectile, lathe-cut from a solid proprietary metal rod. Initial projectiles are made in two weights: .305gr and 419gr. At this stage of manufacturing, the solid design gives the projectile some armor piercing capabilities over what would be found in a lead-core copper jacketed non-armor piercing projectile. Thus, solid projectiles start with an advantage leading to a much more efficient final armor-piercing projectile.

A novel armor-piercing projectile design with a tungsten carbide penetrator was invented by me (US Patent 7,520,224 B2)6. For testing the novel design, a 40 caliber was selected in the .408 caliber. A 27-page White Paper7entitled, A Novel Armor-Piercing (AP) Projectile Design: Illustrated by the .408 Caliber is available upon request. The White Paper contains all details of the study including Materials and Methods, Results and Conclusion.

All testing was conducted at Arco, Idaho with an elevation of 5325 feet. Mean muzzle velocities for the following:

305gr ball = 3250 fps

419gr ball = 2850 fps

305gr (370gr) AP = 3125 fps

419gr (490gr) AP = 2650 fps

Note 1: Even though a 305gr (370gr AP) was tested, the focus here will be on the 419gr (490gr AP).

Note 2: We used .50 SLAP as a control as it gives better performance than the .50 AP (Black & Silver Tips). It requires a special barrel. Analysis of .50 is in my White Paper7.

The new armor-piercing cartridge was tested against steel and titanium armor, and it outperformed .50 BMG AP (Black Tip [M2] and Silver Tip [M8]) under identical conditions.

Terminal Ballistics Results:

100 yds, WearAlloy ½” AR 550 armor steel

305gr ball @ 90 degrees – perforated*

419gr ball @ 90 degrees — perforated.

305gr (370gr) AP @ 90 degrees – perforated*

419gr (490gr) AP @ 90 degrees – perforated.

*The 305gr displayed a sharper cut in the armor over the 419gr

100 yds, WearAlloy ¾” AR 550 armor steel

305gr ball @ 90 degrees – penetrated but did not perforate.

419gr ball @ 90 degrees – penetrated but did not perforate.

305gr (370gr) AP @ 90 degrees – perforated.

419gr (490gr) AP @ 90 degrees – perforated.

100 yds, WearAlloy 1” AR 550 armor steel

305gr ball @ 90 degrees – penetrated but did not perforate

419gr ball @ 90 degrees – penetrated but did not perforate.

305gr (370gr) AP @ 90 degrees – perforated*

419gr (490gr) AP @ 90 degrees – penetrate but did not perforate.

50 AP Silver and Black Tip @ 90 degrees – penetrated but did not perforate**

.50 SLAP – perforated.

*Some perforation was encountered, which can be described as plugging. Perforation was not consistent.

** Those 305gr (370gr) AP and 419 (490gr) that did not penetrate went deeper into the armor than the .50 AP Silver and Black Tips. The 305gr (370gr) AP went deeper than the 419gr (490gr) projectiles.

500 yds, WearAlloy 3/8” AR 550 armor steel

305gr ball @ 90 degrees – penetrated but did not perforate.

419gr ball @ 90 degrees – penetrated but did not perforate.

305gr (370gr) AP @ 90 degrees – perforated.

419gr (490gr) AP @ 90 degrees – perforated.

________________________________________________________________________________________________________

650 yds, WearAlloy 3/8” AR 550 armor steel

419gr ball @ 90 degrees – penetrated but did not perforate.

305gr (370gr) AP @ 90 degrees – perforated but went beyond 1 MOA.

175 yds, WearAlloy ¾” AR 550 armor steel

419gr ball @ 90 degrees – penetrated but did not perforate.

419gr (490gr) AP @ 45-degree angle – 70 % penetration

419gr (490gr) AP @ close to 0-degree angle – 40% penetration

419gr (490gr) AP @ 90 degrees – 90%

Sample sizes ranged from 1 to 5.

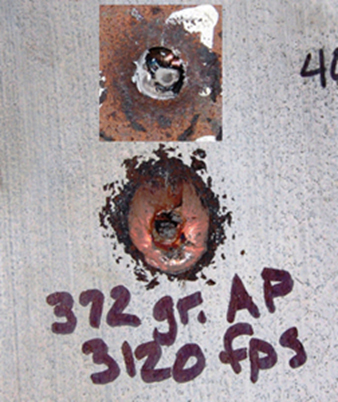

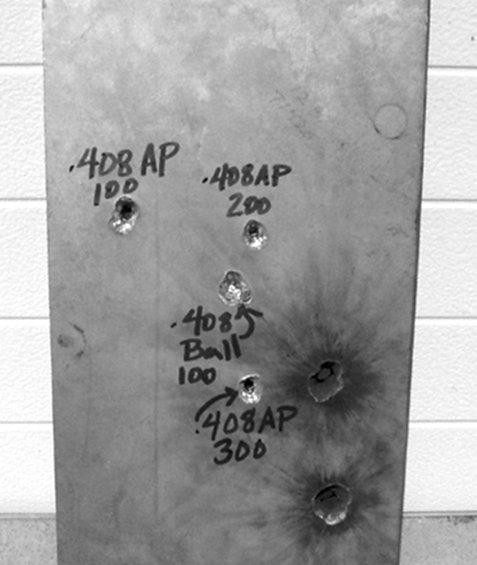

Visual Examples of Terminal Ballistics:

Figure 4.

Top, .408 AP perforates 1-inch armor steel at 100 yards. Insert, back of armor plate showing hole. Bottom, .50 AP (Silver). Armor plate displays penetration but no perforation./strong>

Figure 12.

One-inch titanium armor (laminated plates). The .408 ball did not penetrate but .408 AP penetrated at 100, 200 and 300 yards.

Results of the Terminal Ballistics Data:

Focusing only on the .408 AP terminal ballistics results against the .50 AP (Black & Silver Tips) demonstrated that the .408 had superior terminal ballistics using armor as a test medium.

The M2 Machinegun in .50 Caliber: Its future:

The M2 machinegun is a John Browning design and takes its origin from WW I – first in the .30-06 caliber and later in the .50 BMG caliber. It is approximately 84 lbs. without the tripod. If it is attached to a vehicle or airplane it is fixed in place and does not have to be moved. However, if carried on the battlefield both platform and tripod have to be carried manually. The military talked for years to reduce the weight of the M2. Recently, the Army decided to reduce the weight by 20 to 30% by replace steel parts by titanium parts8-10. Assuming they reach 30%, that leaves a firing platform weighing approximately 74 lb. Is this a major step forward in reducing the weight of the M2? No!

Proposal to Reduce the Size/Weight of the M2 Machinegun while Increasing Ballistics Effectiveness:

We propose to reduce the weight of the M2 firing platform by 40 to 50%. This reduction in weight would be accompanied by a reduction in size. The key is the M2 being chambered for the .408 ball and AP rather than the .50 ball and AP.

Clearly the use of light metal alloys to reduce weight in the new M2 receiver is an option, but the barrel, a major weight component of firing platform needs to be addressed as well. We proposed to extend on-going research with refractive metals such as tantalum alloy liners11. Tantalum and its alloys are extremely corrosive resistant with a melting of 2,996 o C (5,425 o F) and have been shown to extend machinegun barrel life. A Tantalum liner represents the inner tube of a barrel. The rifling would be made Flow Forming Technology12. The out tube must be light in order to reduce barrel weight. There are several directions to go, including light metal alloys however we are looking at new developments in composites – identifying the best chemical formula that works well with a Tantalum liner.

John D. Taylor, Ph.D.

Professor Emeritus

Fellow Emeritus, AAAS

Date: July 26, 2019

References:

1Taylor, J. D. 1997. Parental Cartridge Cases: The Future. Shooter’s News, June, pp. 15-27.

2Taylor, J. D. 1998. .408 Cheyenne Tactical™ — A Novel 2,000-Meter Tactical Cartridge. Part I. Tactical Shooter, Vol. 1, No. 2, pp. 70-74.

3Taylor, J. D. 2000. .408 Cheyenne Tactical™ — A Novel 2,000-Meter Tactical Cartridge. Part II. Tactical Shooter, Vol. 3, No. 4, pp. 5-20.

4Jensen, W. S. 2003. Controlled Spin Projectiles. US Patent 6629669 B2.

5Omanoff, D. & J. D. Taylor. 2017. Small Arms Projectile. DU Patent. Pending.

6Taylor, J. D. 2009. Advanced Armor-piercing Projectile Construction and Method. US Patent 7520224 B2.

7Taylor, J. D. 2006. A Novel Armor-Piercing (AP) Projectile Design: Illustrated by the .408 Caliber. White Paper. 27pp. Requests for this WP should be sent to Dr. John D. Taylor, john@nextgentactical.net

8Osborn, K. 2017. The U.S. Army’s Quest For a Lethal New .50 Machine Gun. The National Interest.https://nationalinterest.org/blog/the-buzz/the-us-armys-quest-lethal-new-50-machine-gun-15948

9Osborn, K. 2017. Army Builds New Lightweight .50-Cal Machine Gun. Scout Warrior. https://www.scout.com/military/warrior/story/1664393-army-builds-new-lightweight-50-cal-gun

10Osborn, K. 2017. US Army to Create Lightweight .50 Caliber Machine Gun (Again). The Firearms Blog. https://www.thefirearmblog.com/blog/2016/04/27/us-army-create-lightweight-50-caliber-machine-gun/

11Taylor, D. J. 2012. Explosively-Clad, Refractory Metal Liners for Small Caliber Machinegun Barrels. Materials and Manufacturing Processes, 27:825-828.

12Fonte, M. V. 2010. Flow forming Gun Barrels and Similar Tubular Devices. US Patent 20100236122 A1.