Executive Summary:

The term sabot is a French term meaning hollow shoe. However, in the science of Ballistics, the term sabot mean a device which ensures that a sub-caliber projectile remains in the center as it travels down a larger caliber barrel. After the projectile leaves the muzzle, the sabot falls away from the projectile1. The new invention is called RiderSabot™. It is a new device that positions a medium-density sub-caliber projectile (with or without penetrator) in the center of the barrel without it coming into contact with the rifling. The density of the RiderSabot™ is less than barrel steel thus successfully engaging the lands and grooves of the rifling. In addition, it contributes to the external ballistics of the projectile as its aft portion displays a boat-tail configuration designed for long-distance target engagements. As the projectile with its RiderSabot™ leaves the muzzle, it does not fall away from the projectile but accompanies the projectile to the target. The composition of the RiderSabot™ is a polymer composite displaying engraving characteristics not as dense as barrel steel thus insuring successful engraving onto the rifling with reduced resistance. A number of polymer composites fit this description and the one selected will fits desired caliber and ballistics. The significance of the RiderSabot™ is to serve as a low-density carrier for a medium dense projectile (with or without penetrators) that is denser than the barrel steel while at the same time its aft boat-tail configuration contributes to the successful long-distance trajectory.

In sum, the RiderSabot™ serves as a low-density carrier for a medium dense projectile with or without high-density penetrators, stays with the projectile in flight and it boat-tail contributes to successful external ballistics to the target. It is intended for armor to hard target interdiction.

INTRODUCTION:

The term sabot is French for a hollow shoe. In the science of Ballistics, the purpose of the sabot is to carry a sub-caliber metal cargo; i.e., slug, shot, a projectile in a larger caliber barrel without touching the lands and grooves of the rifling. Once the sabot and cargo have left the muzzle, the sabot separates from the cargo, falls to the ground while the cargo continues to the target. Sabots come in different designs but the common thread that runs through all designs is to carry cargo through the barrel and drop away to the ground while the cargo continues on to the target. Some designs work better than others mainly because to one degree or another, as the sabot leaves the cargo – the act of leaving influences the external ballistics, including accuracy, distance traveled and stability of the cargo. This, in turn, has an effect on the terminal ballistics of the cargo.

If the cargo turns out to be a sub-caliber projectile, the intention is to achieve muzzle velocities that are greater than the caliber of the barrel because of extra propellant use to increase the velocity of the sub-caliber projectile. Separation of sabot from projectile still retains the possibility of a negative influence on the external ballistics of that projectile.

Projectiles with hard target interdiction capabilities are becoming more common in today’s tactical situations. The capabilities range from armor-piercing (AP) with heavy metal penetrators such as tungsten and uranium to targets with less density such as walls, vehicle bodies, body armor, etc. The latter can be found with penetrators of hardened steel to dense projectiles made of tellurium copper alloys without penetrators. Due to their high densities, these hard target interdiction projectiles are heavier than the same projectile without a penetrator. The extra weight reduces projectile velocity which has a direct effect on terminal ballistics.

I have had success with armor-piercing projectiles made of Tellurium-Copper alloy projectiles2,3 carrying tungsten penetrators4. In 40 caliber, it outperforms 50 calibers AP projectiles against armor5.

I asked the question, could we design a sabot that is part of the projectile and eliminate the negative features of the traditional sabot? The answer is a new design called the RiderSabot™ where the sabot is part of the projectile and does not leave the projectile once the projectile leaves the muzzle.

NEW DESIGN:

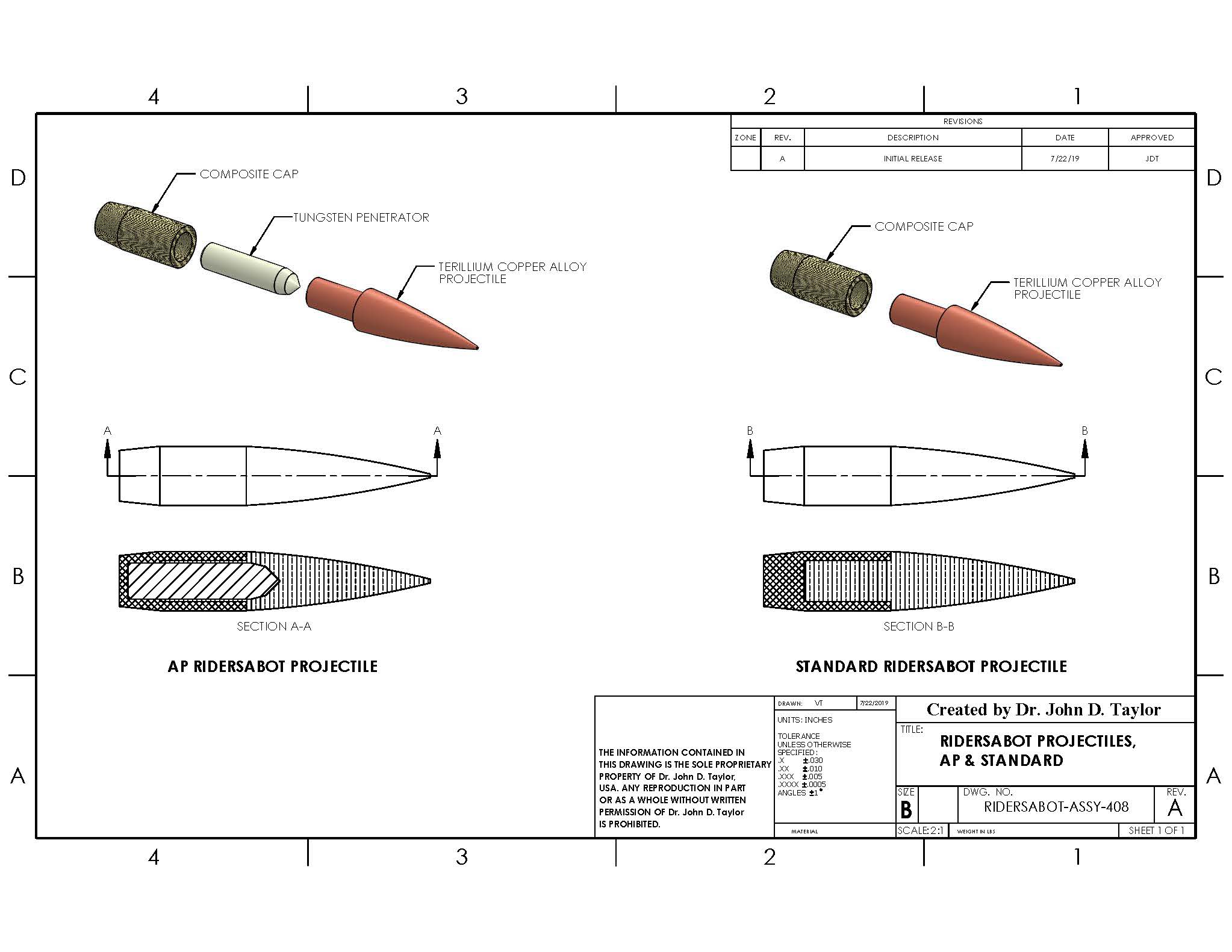

Figure 1. Illustration of the new invention, the RiderSabot™. The composite RiderSabot™ is ‘press-fit’ to the rear of a Trillium-Copper Alloy Projectile.

NOTE 1: The above illustration does not best illustrate the RiderSabot™ and its components. The final version of this White Paper will include several figures to clearly identify the RiderSabot™ and each component relationship to one another.

RiderSabot™ is illustrated in Figure 1. It makes up the rear of the total projectile unit. Together they are called the RiderSabot™ Projectile Unit. It is press-fit to the Tellurium-Copper alloy projectile. In some cases, the projectile will contain a heavy metal penetrator such as tungsten or uranium. In other cases, it will not. So, the RiderSabot Projectile Unit either is intended for armored or hardened targets.

The outer diameter (OD) of the RiderSabot™ is designed to engage the lands and grooves of the barrel rifling. Note the boat-tail and ogive of the projectile do not come in contact with the rifling. The rear of the projectiles OD is such that it fits into the inner diameter (ID) of the forward end of the RiderSabot™. Depending on whether the projectile carries a heavy metal penetrator or not, the design will reflect such. In the case the projectile is not carrying a penetrator, its OD base will fit the ID of the RiderSabot™ chamber.

At the time of the ignition of powder, the floor, as well as the top of RiderSabot’s wall, will ‘push’ the projectile into the lands and grooves of the rifling. As the RiderSabot Projectile Unit moves through the barrel the RiderSabot Projectile Unit will remain together. If the projectile contains a heavy metal penetrator, the movement through the barrel will be the same.

NOTE 2: A potential criticism exists that the ‘press-fit’ will not be enough to keep the RiderSabot™ Projectile Unit together as it travels through the barrel and remain together until it hits the target. This will be addressed in a patent application after tests are conducted if it turns out to be a problem. One possible solution is a small amount of adhesive resin added to the cavity of the RiderSabot™ to ensure it stays connected to the projectile.

The RiderSabot™ has a built-in boattail. The design is a mechanical way to reduce the aerodynamic drag at the projectile’s base6. Boat-tail designs with an angle close to 7 degrees, depending on caliber are critical for long distances.

The RiderSabot™ is composed of a polymer composite. Its formula has yet to be identified. However, the physical extremes that the successful composite will face have been identified. These include physical extremes during the time of powder ignition until the RiderSabot™ Unit leaves the muzzle. The two composite companies that General Dynamics recommended to provide composite in rod form for Swiss lathe and/or CNC have been unresponsive to my inquiries. This needs to be followed up.

The RiderSabot™ design of the new invention is intended for all small arms calibers. What is open in my mind is whether the design is marketable for canon calibers. Clearly, it would have to offer something new in battlefield tactics that are not available with current designs.

Upon acceptance of the final design, we will add dimensions with respect to caliber via SolidWorks.

DISCUSSION AND SIGNIFICANCE:

Whether the RiderSabot™ Projectile Unit carries a penetrator or not, both designs address hard target interdiction with capabilities ranging from armor-piercing to harden targets. In addition, since the composite RiderSabot™ engraves the rifling instead of dense material such as a metal, the exiting projectile from the muzzle has greater speed and kinetic energy than projectiles using metal to engraves metal.

The RiderSabot™ stays with the projectile (with or without penetrator) and thus there are no negative ill effects as seen when the sabot falls away from the projectile.

The RiderSabot™ in a RiderSabot™ Projectile Unit configuration opens new and extend existing battlefield tactics. As such, it has a high probability of being accepted by the military in those calibers of their interest.

There is a high probability that the Patent and Trademark Office will approve registering the mark ‘RiderSabot.’ This leads to potential licensing agreements.

There is a high probability that the Patent and Trademark Office will patent the new invention assuming we have a patent attorney that can write a tight application.

John D. Taylor, Ph.D.

Professor Emeritus

Fellow Emeritus, AAAS Fellow

July 7, 2019

ACKNOWLEDGMENTS:

The author would like to thank Victoria Trafka, MS ME, Engineering & Quality Solutions, Inc. for SolidWorks contributions to the research with this project.

References:

- Merriam-Webster Dictionary. a device which ensures the correct positioning of a bullet or shell in the barrel of a gun, attached either to the projectile or inside the barrel and falling away as it leaves the muzzle. 2019. https://www.merriam-webster.com/dictionary/sabot

- Taylor, J. D. 1998. .408 Cheyenne Tactical™ — A Novel 2,000-Meter Tactical Cartridge. Part I. Tactical Shooter, Vol. 1, No. 2, pp. 70-74.

- Taylor, J. D. 2000. .408 Cheyenne Tactical™ — A Novel 2,000-Meter Tactical Cartridge. Part II. Tactical Shooter, Vol. 3, No. 4, pp. 5-20.

- Taylor, J. D. 2009. Advanced Armor-Piercing Projectile Construction and Method. U.S. Patent No. 7,520,224.

- Taylor, J. D. 2008. A Novel Armor-Piercing (AP) Projectile Design: Illustrated by the .408 Caliber. White Paper.

- Platou, A. 1974. An Improved Projectile Boat Tail. National Technical Information Service https://www.dtic.mil/dtic/tr/fulltext/u2/785520.pdf